Mr. Richard SHEN

Leave a message

Mr. Richard SHEN

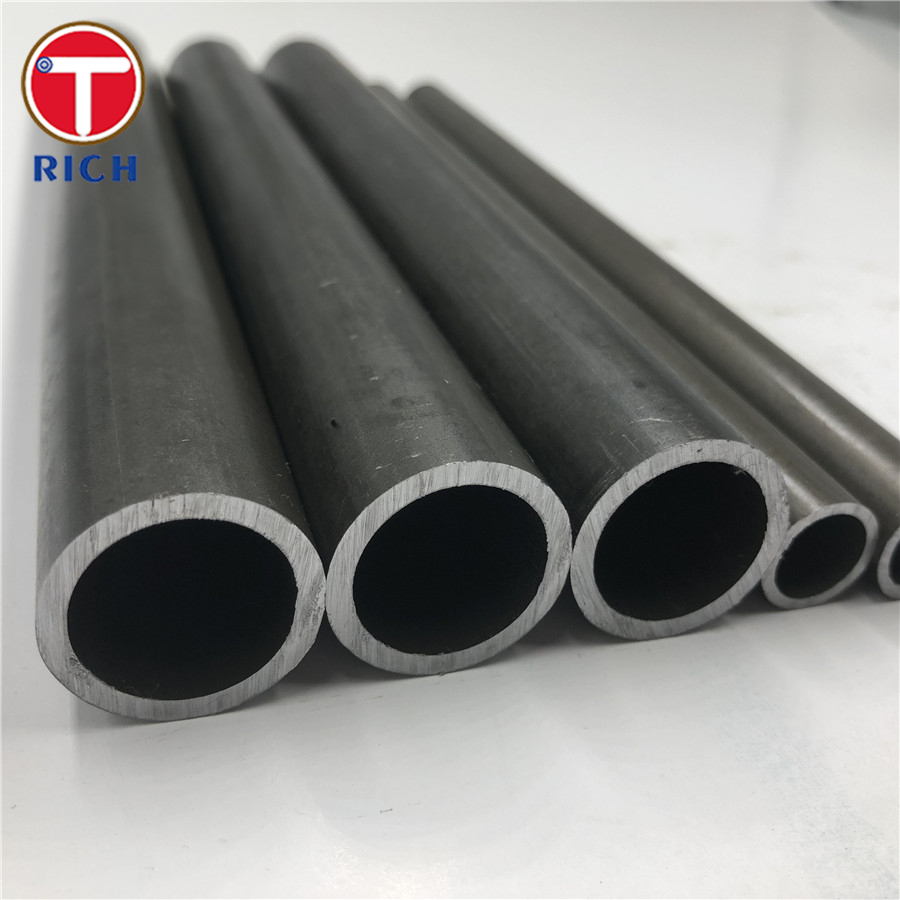

Leave a messageSteel tubing is a common material used in various industries, including construction, automotive, and manufacturing. Its strength and versatility make it an ideal choice for structural support, transportation of fluids and gases, and other applications. However, not all steel tubing is created equal when it comes to strength. In this article, we will explore three questions regarding the strongest type of steel tubing and provide answers to draw a conclusion.

The strength of steel tubing depends on several factors, including the grade of steel, the manufacturing process, and the tube's dimensions. Different grades of steel have varying amounts of alloying elements, such as carbon, manganese, and chromium, which affect its strength. Manufacturing processes like hot rolling, cold drawing, or seamless manufacturing also impact the tubing's strength. Additionally, the tube's dimensions, such as wall thickness and diameter, play a crucial role in determining its strength.

Among the most common types of steel tubing renowned for their strength are:

a. DOM (Drawn Over Mandrel) tubing: DOM tubing is created by drawing a Steel Tube over a mandrel, resulting in a seamless and highly uniform product. The manufacturing process enhances the tube's strength, allowing it to withstand high mechanical stress while maintaining dimensional accuracy.

b. Chromoly steel tubing: Chromoly, or chromium-molybdenum steel, features excellent strength-to-weight ratio and corrosion resistance. With added alloying elements, such as chromium and molybdenum, this type of tubing becomes significantly stronger than regular steel tubing.

c. Stainless Steel tubing: Stainless steel is inherently known for its corrosion resistance, but certain grades, such as 316 and 304, also offer remarkable strength. This tubing is commonly used in environments where corrosion and high strength are both essential.

Determining the absolute strongest type of steel tubing can be subjective as it depends on the specific application requirements and constraints. However, one type that stands out in terms of sheer strength and durability is:

d. Carbon fiber-reinforced polymer (CFRP) tubing: While not purely steel, CFRP tubing deserves mention due to its exceptional strength-to-weight ratio. Carbon fibers within a polymer matrix provide high tensile strength, rigidity, and resistance to fatigue. CFRP tubing is commonly used in high-performance applications such as aerospace and sports equipment where strength is a critical factor.

The strength of steel tubing is determined by various factors such as the grade of steel, manufacturing processes, and dimensional specifications. While DOM tubing, chromoly steel tubing, and high-strength stainless steel tubing are widely recognized for their strength, the title of the strongest type of steel tubing goes to carbon fiber-reinforced polymer (CFRP) tubing due to its extraordinary strength-to-weight ratio. However, it's crucial to consider the specific requirements of each application before selecting the optimal type of steel tubing.

Previous: What are the four types of metal tubing?

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.